Sip Wall Panels Reviews

Sips are also known as foam core panels stress skin panels sandwich panels and structural foam panels.

Sip wall panels reviews. However wall roof or floor panels bigger than eight by eight feet require a crane or forklift. Thermocore structural insulated panel systems sips are the world s most energy efficient way to build homes and buildings. The panels are composed of a laminate and foam core. To reduce cost and waste architects should design panel size friendly sip walls without excessive jogs bump outs or non 90 degree angles.

About 12 000 homes were built with sips in 2002 according to the gig harbor wash based structural insulated panel association considering how many houses are erected annually this number is barely a blip. Issues with structural insulated panels sip dr. Detailed information about osb are pests are a problem with sips spoiler they re not an r value overview why you don t need to. As any builder can attest non straight dimensional lumber can negatively impact any stage of the building process including cost and building time.

Nabil taha has over 27 years of structural engineering experience. Structural insulated panels disadvantages to consider. We answer the most common questions about building with structural insulated panels on our sip faq page the topics include. Workers can manually move and handle small sip panels.

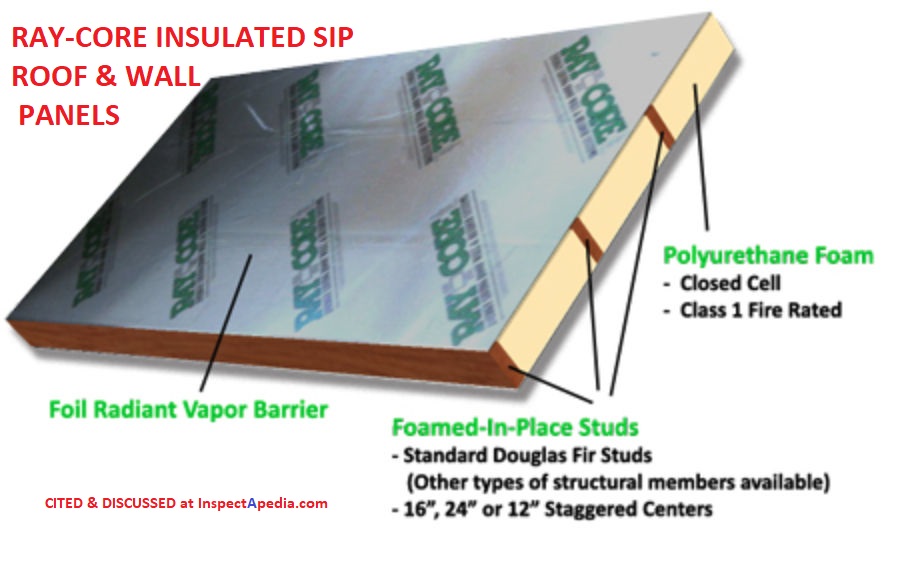

Ray core structural insulated wall panels will give you a strong super insulated airtight shell keeping the outdoor elements out and the indoor conditioning in. Australian design builder habitech systems uses them to build. Prior to opening his own engineering firm in oregon in 1997 he was a professor of engineering at northern montana state university and at oregon institute of technology. If you do not have experience building with sips you probably have a lot of questions.

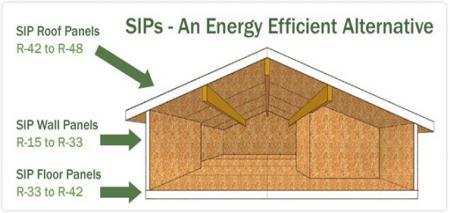

Their thickness is between 4 and 8 inches and they can be used for traditional walls. Structural insulated panels are like an oreo cookie with a foam filling and and osb oriented strand board or plywood on the outside. By now familiar to most builders sips are made from expanded polystyrene eps or polyisocyanurate rigid foam insulation sandwiched between two structural sheets of oriented strand board. Structural insulated panels sometimes referred to as sips are composed of laminate with a foam core that is between 4 and 8 inches thick with a structural facing such as drywall or plywood on each side.

Why build with structural insulated panels. Limited design options with sip walls.