Sliding Sleeve Door Profile

It required two strokes to fully open the sliding sleeve door.

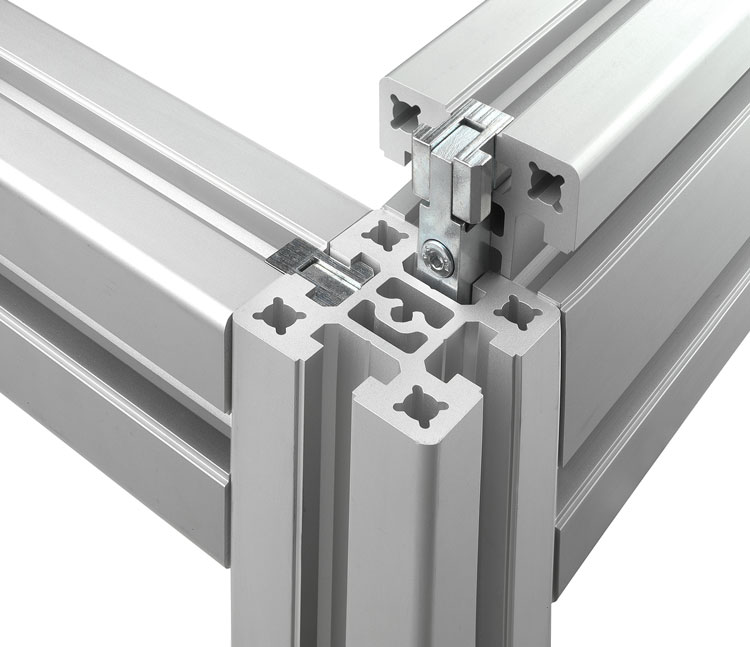

Sliding sleeve door profile. The positioning tool engages the recess in the upper or lower end of the sleeve to enable the sleeve to be shifted by a jarring action. Sliding sleeve wp 5000 10000psi profile type f. Equalizing pressure between the tubing and casing annulus is normally accomplished by applying pressure or filling the tubing or casing with fluid. Move the inner sleeve to its open or closed position in the type xa ra xo and xd halliburton otis sliding side door circulating sleeve.

Empacador de camisa deslizable. The slxo sliding sleevehas an otis x style selective nipple profile and a seal bore in the upper sub which serves as a receptacle for other flow control devices such as blanking plugs and separation tools. The open up optisleeve u configuration or the open down optisleeve d configuration. The slxo sliding sleeve can be installed at any point in the tubing string.

The sliding sleeve packoff is attached to a lock which anchors and seals in the sliding sleeve. The optisleeve sliding sleeve is available with an integral nipple profile. The lower sub also contains a seal bore. The sls series sliding sleeves are used in the separate zone production to switch the tubing and casing annulus.

All versions of the optisleeve sliding sleeve are available in either common oilfield alloy or corrosion. The well tractor powered up to engage the well key profile to the shifting profile. Sliding sleeves with x d db and ds nipple profiles separation tools and packoffs are available. A nipple profile in the top sub and a polished bore in the bottom sub are standard features and allow accessory tools such as a side door choke or separation tool to be set across the durasleeve device.

It incorporates an internal sleeve that when open enables communication between the tubing and tubing casing annulus. The well stroker configured with 15 000 lbs force anchored in position on the 5 1 2 20 blank pipe above the sliding sleeve and powered up to stroke down and shift open the sleeve. This product can be shifted open or closed by the wireline tool string installed with the shifting tool. The packoff assembly isolates the sliding sleeve ports and prevents fluid migration between the tubing and casing annulus while allowing restricted flow up the production tubing from below.

The durasleeve sliding side door circulation and production sleeve is a full opening device that can be operated using standard slickline methods. The sliding sleeve can also be opened even if.