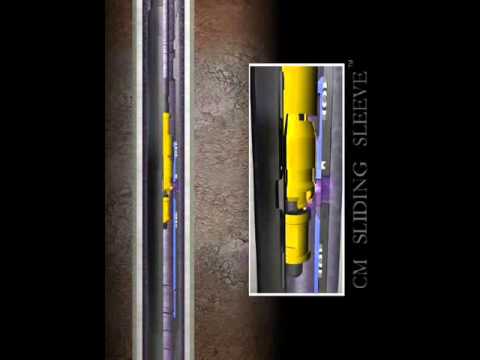

Sliding Sleeve Door

A sliding sleeve is a standard component for the completion of an oil or gas well.

Sliding sleeve door. Tendeka s ssd enables selective flow in production and injection directions. This is the first sliding knee pad i ve bought so i have nothing to compare it to. Move the inner sleeve to its open or closed position in the type xa ra xo and xd halliburton otis sliding side door circulating sleeve. Their main uses are to shut off flow from one or more reservoir zones or to regulate pressure between zones.

The material and construction are excellent which is typical mcdavid i ve used their braces. The durasleeve sliding side door circulating and production sleeve is a full opening device that can be operated using standard slickline methods. The pad is easy to slip on and comfortable to wear. The packoff assembly isolates the sliding sleeve ports and prevents fluid migration between the tubing and casing annulus while allowing restricted flow up the production tubing from below.

The ssd can be combined with tendeka s inflow technologies to provide inflow control when in the open position. It incorporates an internal sleeve that when open enables communication between the tubing and tubing casing annulus. The positioning tool engages the recess in the upper or lower end of the sleeve to enable the sleeve to be shifted by a jarring action. The tool is designed to release itself only after the sleeve.

Here are my impressions. The sliding sleeve packoff is attached to a lock which anchors and seals in the sliding sleeve. Sliding side door ssd open close sliding sleeve ssd enabling selective flow for production and injection applications. The tool has one connection which minimizes potential leak paths the non elastomeric seal.

By all accounts it is good protection where you may need it. Selective and or top no go locking devices are available for use with the sleeve. The act model l sliding sleeve is a downhole tool used to establish communication when desired between the tubing and annulus.